My sister in the US recently bought a smartly embroidered top for 35 dollars (about 1500 rupees), and was amused to find a 'Made in India' tag. Had she known that only 1.8 dollars of the retail price was spent on paying for labour, she would have been much less amused.

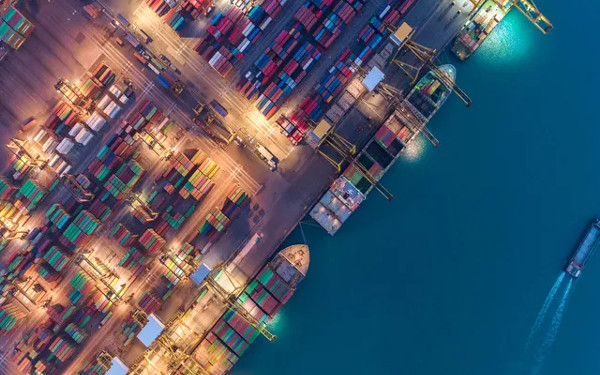

While India's garment sector earns high export revenue, the flip side is that the substantial profit accruing to foreign retailers and, to a lesser extent, Indian manufacturers is not reflected in garment workers' wages. Asian countries dominate global trade in readymade garments. In 2004, Asian trade in this sector was to the tune of 138 billion US dollars (UN Comtrade data). In Bangalore alone, large retail chains from the US and Europe - like GAP, Walmart, Tommy Hilfiger and JC Penny - have outsourced orders to large factories to the tune of 269.6 million US dollars in 2005. (Source: an unpublished 2005 report prepared by Mark Francoise of the US-based United Students Against Sweatshops.)

The industry's predominantly women workers are "first-generation workers who have no tradition of organising." They face many hurdles in undertaking any form of collective action.

•

Where dignity is auctioned

•

At home, at work

•

Minimised by the law

•

Too little, for too long

•

An independent voice for workers

The Indian garment industry workforce predominantly comprises first-generation women workers. In the bigger factories in Bangalore, it has been estimated by K R Jayaram, Field Coordinator, CIVIDEP (Civil Initiatives for Peace and Development), which works with garment workers in the Mysore Road area, that 50-70 per cent of garment workers are the sole earners in their family.

Single parent Jayamala (name changed), a tailor, earns Rs 2,450 a month; and because tailoring is skilled work, this is at the higher end of the wage scale. But with two school-going children, she finds it difficult to make ends meet. Food comprising only the cheapest vegetables - constitutes the biggest expenditure. Fuel needs are scarcely met through kerosene and firewood. Public transport buses are money guzzlers, and Jayamala uses private tempos and lorries at Rs 3 a day. For other necessary expenditure, such as medical treatment, she is constrained to take loans at exorbitant interest rates.

However, instituting a 'fair wage' in the export-oriented garment manufacturing concerns is very tricky. Industrial adjudicators cannot just look at the capacity of the industry to pay, as they would in the case of industries catering to the domestic market. For starters, they have no jurisdiction over foreign retail chains as there is no employer-employee relationship between the latter and the garment workers. Then, the earnings of manufacturers in the garment industry are not enough to pay the "need-based minimum wage" - wages that provide for the efficiency of the worker through education, medical and other benefits (elaborated upon in landmark Supreme Court judgements like Unnichoye's case in 1962 and Reptakos Brett's in 1992).

The crucial aspect here is that foreign buyers chalk up a huge profit margin. Take the 35 dollar top: the total cost to the brand until it reaches the retailer's country is only 10 dollars. Even accounting for warehousing costs, designer's fees and other miscellaneous costs, the retailing chain still makes supernormal profits.

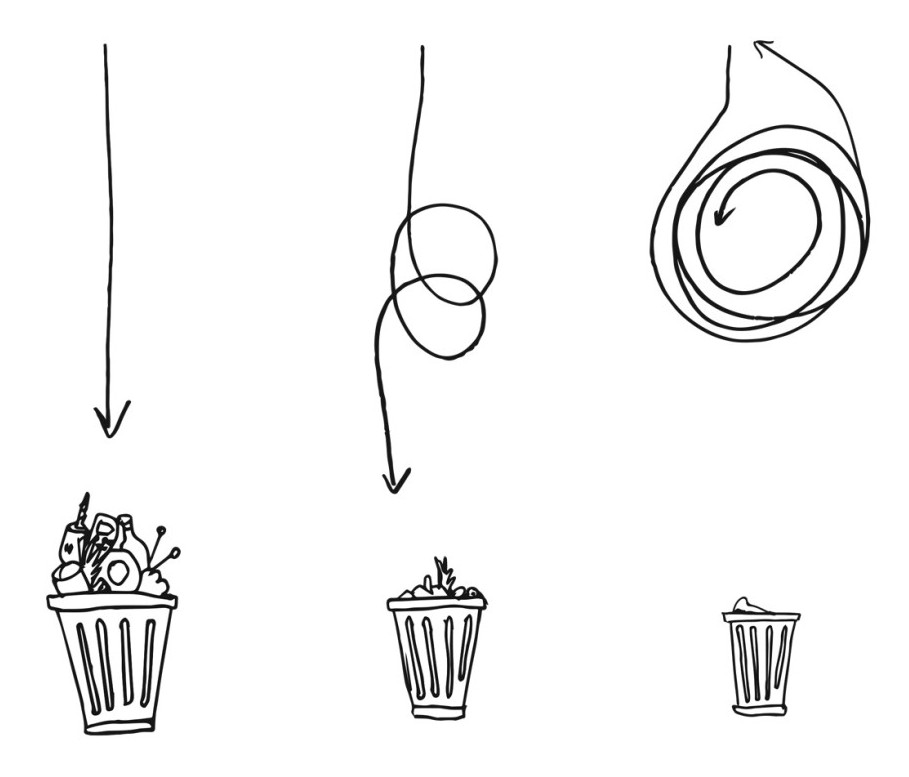

Assuming that activists and trade unions in India do agitate to increase wage scales in the garment industry, manufacturers would point out that if their labour costs - and hence billing costs - increase, buyers would shift their business to a cheaper garment-exporting region, like Bangladesh or Indonesia. A real possibility in the post-quota system era (after January 2005), where there is no longer a limit on the quantity of garments imported from a certain country.

This has prompted enterprises in South Asia, which handles the bulk of global garment outsourced manufacturing, to make their products more price-competitive by squeezing the only 'flexible' factor of production - labour. Workers are not being paid even statutory wages, as payment is linked to reaching unreasonably high production targets - simply put, unpaid overtime.

A campaign for an Asia-level wage for garment workers in exports intends to stop this "race to the bottom" vis-à-vis wages. The campaign has been initiated by some Indian NGOs - CIVIDEP, FEDINA (Foundations for Educational Innovations in Asia) and Stree Jagruthi Samiti (Bangalore), CEC (Centre for Education and Communications) (Delhi), and SAVE (Tirupur) - along with the New Delhi-based trade union coalition New Trade Union Initiative and the US-based coalition of trade unions and civil society organisations Jobs with Justice. They now hope to involve organisations in other parts of Asia who work with workers in garment-exporting concerns.

Their idea is that if a uniform and decent wage is introduced in the region, countries can compete on the basis of other strengths and not at the cost of workers. Current wages in South Asia hover around the same level. If all these countries rally around a uniform floor-level wage, they would have significant leverage to achieve their demand.

In today's marker economy, any additional cost to the manufacturer is passed on to the consumer. This is the likely scenario in the case of garment exports as well, supernormal profits notwithstanding. However, if the garment worker's wages are doubled, it would mean a mere 2-4 per cent increase in retail price. A sample survey of customers in the US indicated that they were willing to accept this marginal increase, particularly if they were made aware of the reasons behind it (quoted in a paper by Pollin, Burns and Heinz, University of Massachusetts, 2000).

While the economics of the proposed campaign appear sound, is it realistic and doable? After all, it marks a shift from traditional methods of workers' struggle and projects new ways of collective bargaining. C Gopinath, Director, CIVIDEP, argues that this is necessitated by the fact that, presently, the industry's predominantly women workers are "first-generation workers who have no tradition of organising." They face many hurdles in undertaking any form of collective action, not least of which are pugnacious managers who threaten immediate dismissal if workers dare ask for a raise.

However, a labour lawyer with a communist party legal cell in Bangalore challenges the very basis of the concept. He believes that focusing on only the large garment exporting companies in each of these countries will create "wage islands" and discriminate against garment workers who produce goods for the domestic market, when there is no difference in the nature of work or level of skill required.

Accepting that there will be discrimination, Gopinath nevertheless contends that it is within the logic of the global garment supply chain that the strongest, most organisable section of workers will be picked. Gains achieved by this sector will have a "trickle down effect." Manufacturers for the domestic market will feel the pressure to improve working conditions and an impulse to organise will be generated amongst workers in these concerns, he feels.

The economic imbalance, he points out, is "in the utter exploitation of the workers...in the global supply chain with the retailers cornering gains at the expense of workers. Asian workers are producing two-thirds of the world's garment manufacture and they must get a social wage," he says. (Women's Feature Service)