True, thousands of small scale and even some bigger industrial units simply dump their waste, more often toxic and hazardous, in open spaces and nearby water sources. Over the last three decades, many cases of serious and permanent damage to environment by these industries have come to the fore.

While strict pollution control norms are in place, they are dodged by many industrial units either hoodwinking or managing the state pollution control boards. However, there is gradual change of the mindset and in the attitudes of the people running manufacturing business. And some industries are making attempts to keep up to the norms and trying innovative methods, may be to get ISO 14000 certification.

The latest that is happening in pollution control is the research on vermicomposting of industrial sludge being tested out in some industries. Dr Suneet Dabke is putting his research on vermicomposting of toxic industrial waste into practice for the last 3-4 years. It is only after observing the results over fairly long period that he would be able to establish this process as an answer to managing the industrial waste issue. Dabke is based in Gujarat.

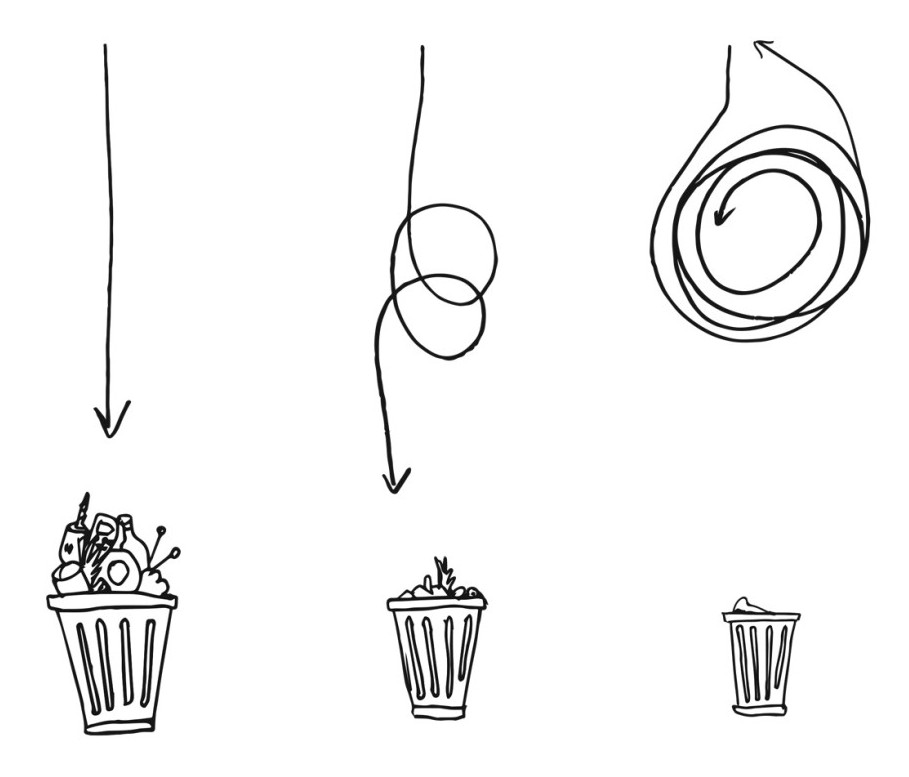

The present technologies for disposal of solid waste are either incineration or landfilling (may be so-called scientific land filling). But the disadvantages of these methods are well known. While incineration causes serious air pollution as also generates residual highly concentrated toxic ash, mere dumping or landfilling causes hazards of leachate polluting soil and ground water. Scientific landfilling claims to be safer, yet landfilling of any type needs much land. The other technology is composting by spreading out the waste on land. This also takes up land, and is accompanied by serious problems of direct soil contamination.

However, Dr Dabkes method works on the sludge that remains after the effluent treatment. Bigger industries can afford their own effluent treatment plant while smaller units can join together to send their effluents treated as per the PCB norms within the factory to the common effluent treatment plants (CETP) for further treatment. While the sludge settles down, the clearer water outflows into outer drainage system. It is this sludge which still has about 70-80 per cent water and can be dewatered by a belt press filter. The remaining 20-30 per cent solid sludge contains organic as well as inorganic material. Depending upon the characterisation of the sludge, a predetermined proportion is spread on a vermiculture bed that uses earthworms. Like in conventional vermicomposting, the organic matter from the sludge gets converted into manure. Simply put, this is the process.

• Rethinking waste management

• Gujarat: Toxic corridors

Having developed this concept after testing number of batches with different proportions of industrial sludge and vermiculture (cowdung, bagasse, leaf litter), Dabke has provided it to some medium to large-scale industrial units over last three-four years. Some of the projects executed are treatment of textile sludge of Jagdamba Textile at Narol and Samir Textiles at Odhav in Gujarat; Gujarat Refinery waste into non-toxic manure; paper industry sludge of Vepar Pvt Ltd at Ahmedabad; Dairy waste of Mother Dairy at Gandhinagar; pharma sludge of Aventis Crop Science and Lupin Lab at Ankleshwar; Torrent Pharma at Mehsana in Gujarat. Currently he is working on the pilot projects at Reliance industries Hazira as well as Patalganaga plants.

Dabke, however, says a strict no to waste from dyes and intermediates industrial units as these have a very high proportion of inorganic compounds in their waste. Thus industrial waste sludge that has good proportion of organic matter can be converted into non-toxic manure, thinks Dabke and hence is suitable for textile industry, oil refinery, dairy, distilleries, pulp and paper industry, food processing, agro industries etc. His approach is to carry a detailed characterization of the waste, take up controlled experiments, then large scale experiments and only after establishing the desired results over a sufficiently long period, go in for industrial application.

If vermicomposting toxic industrial waste has proved to be successful, why is it not finding large scale acceptance by the industry as also administration? Dr Dabkes research referee Dr Radha Kale of University of Agriculture Science in Bangalore, has been similarly providing solutions to distilleries in Karnataka. The states pollution control board (KPCB) has already given the consent to this process. However, the Gujarat Pollution Control Board (GPCB) and Maharashtra Pollution Control Board (MPCB) do not seem convinced and have not given their consent. Besides, environmentalists also do not seem very convinced and remain somewhat apprehensive about the process.

According to environmental activists fighting against rampant industrial pollution in Gujarat, any kind of work on industrial sludge or effluent is possible only after detailed characterisation of the waste. No such detailed characterisation of the waste streams in Gujarat has been reported so far, according to them. The best has been done by NEERI for the Amla Khadi of Ankleshwar, but that too was without identifying a single chemical; the study reported loads of carbon, chlorine, etc., only in aggregate levels. The only other good one is done by Greenpeace, but they were only looking for chlorinated organics and heavy metals. Besides such detailed characterization is extremely costly affair.

Environmentalists say that each sample (and one would have to do many, and over a significant period of time) analysis would cost upwards of Rs 30,000 for detailed characterisation, and that too with highly skilled personnel. There is a doubt that whether such facilities exist in India at all. And in fact, for dioxins, India has only two experts in India, and on last count, no testing facility. Like waste, similar characterisation of the vermicompost produced would have to done. So imagine how expensive it would be.

But the question is also about the level of characterization of sludge that is really necessary. Most experts agree that detailed characterisation is expensive. But according to Dabke, characterization need not be that costly. Dabke gets a total load estimate which is not so expensive, but enough to make the decision. (The load estimate is for the level of organic/inorganic compounds in the sludge at the input to the VC process). However, on estimation of toxicity for post-compost residue, Dabke acknowledges that because many batches of sludge need to undergo composting over a considerably long period of time, establishing this level is a time consuming process.

On the operational side, the whole job is made extremely difficult by the fact that the waste streams keep on changing. And therefore it is impossible to have one method of treatment for all these types. Often the volume of the sludge (or effluent) may be too large making it unviable to treat the waste in any sensible manner, opine environmentalists.

Acoording to an expert on pathways of environmental pollutants from University of Colorado, even if the effluent or sludge could be treated, a leftover sludge would be so toxic and persistent that it would demand much specialised care and technique to store, let alone treat. Because of these extreme difficulties encountered in treating toxic waste and prohibitive costs incurred, environmentalists toe the extreme hardline that the only way out is not to produce waste.

But that agreed, the reality also cannot be wished away with the monster of industrial pollution gaping straight in our faces. Having created a system that generates industrial waste in the absence of workable controls, what are the options? Will vermicomposting of at least the industrial waste/sludge that has high proportion of organic waste be an answer at the plant level, if not at the collective stage like CETPs? The application may be industry specific and not a wholesale adoption by the industry sector.

As Dabke puts it, ideally industries should process the biological waste and send the difficult waste to the scientific landfill sites. With vermicomposting, there would be considerable reduction in the volume going to legal landfill or illegal dumping grounds. As per Dr Dabke, the conversion costs are not prohibitive at Rs 3-4 per kg of sludge as against Rs 5-6 per kg for sending it to landfill.