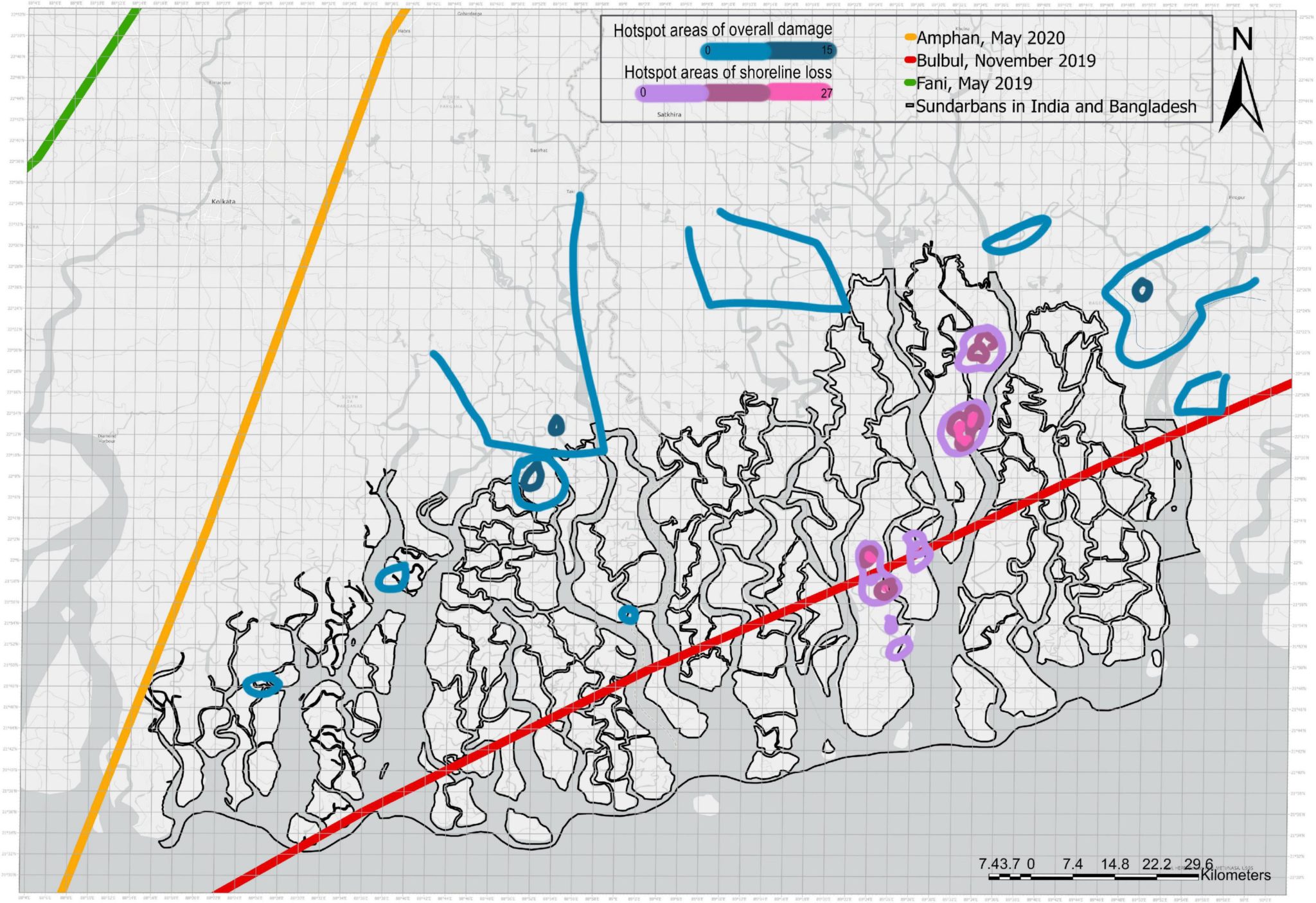

South Indian disposable dinner plates are now popular throughout the world. Interestingly, this is made from a palm leaf. The broad leaf sheath of areca nut (betelnut or supari) palm is an eco-friendly raw material that's well accepted by all. Commercial chappal production from the very same raw material is a recent development.

Those who are allergic to chappals made from synthetic materials like PVC (Polyvinyl chloride) and PVA (Polyvinyl Alcohol) prefer these, points out K A Joseph. His Multicare Company in Thrissur, Kerala, is producing Areca leaf chappals apart from dinner plates.

![]() A broad strap model that is popular. Pic: Shree Padre.

A broad strap model that is popular. Pic: Shree Padre.

Though Multicare started trials with this new product two years ago, marketing was initiated barely few months ago. Now they are selling about 4,000 pairs a month. These are priced from Rs.125-375. In areca leaf chappal, only the top portion of the sole is made from areca leaf. Below this, depending on pattern, one or two layers of rubber will be there.

Commercial utilization of arecanut leaf sheath has a history of just a decade and a half. Though arecanut farmers have been using this bye-product for many household uses, earlier most of the fallen leaves were wasted. Joseph was in Nigeria till recently. After returning his roots in Kerala, he started this industry. He is was aware that decades ago the late S R K Menon had shown the world for the first time the possibility of making chappals from areca leaf.

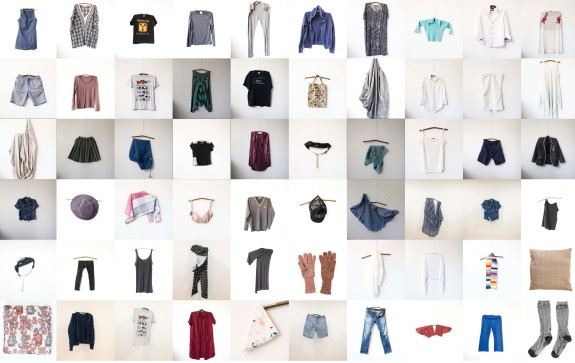

Dream of 35 years

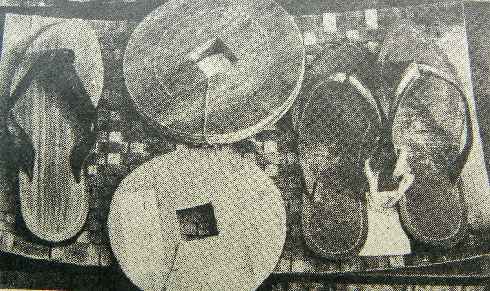

Menon, a retired scientist from North Parur, Kerala was 70 when he came out with areca leaf chappal and other products. In 1975, he had held an exhibition of these products at Central Plantation Crops Research Institute in Vittal, Karnataka. For those who expressed doubts about the durability of areca leaf chappals, he was showing the one he was wearing. See this, I am using this since last two years, he used to reply.

Areca Palm leaf chappals made by late S R K Menon way back in 1975

. Pic: Shree Padre.

Three and half decades after Menon saw various areca leaf products being used worldwide, its chappal has started realizing his dream.

How is that Joseph got this idea of commercially producing areca leaf chappals? He was impressed by straw chappals that are being made at Rajasthan. Its very eco-friendly too. On seeing these straw chappals, it occurred to me why not we make this from areca leaf sheath? he recalls.

But once the experiments started, there were many problems. Making round cuts is very difficult in areca leaf sheath due to the fiber strands. Thickness of any leaf sheath isnt uniform. It has lot of variations. With continuous trial and error, Joseph was able to pass these hurdles.

Then came the question of strap. Making straps from leaf sheath isnt possible. Joseph wanted to stick to eco-friendly material. Searching or one, banana fiber came to his mind. Pleated banana fiber straps conformed to the requirement well. All said and done, finding an alternative to an inch-long plastic tube that covers the front tip of the strap still remains a question.

Seeing the catalogue, the customer has to select from different patterns, strap colors and strap patterns. On indent, the footwear is made and dispatched.

This is by and large an indoor chappal. It cant be used outdoors especially during monsoon. If few drops of water fall on it, not a problem. It can be dried by keeping it vertically. But the chappal cant be allowed to soak.

![]() Chappal with simple narrow strap simple design

. Pic: Shree Padre.

Chappal with simple narrow strap simple design

. Pic: Shree Padre.

Confesses Joseph, The main suspicion of most of customers is about the life-span of a areca chappal.

According to him, if used only indoors, this footwear will last like any rubber slippers. Whatever care one takes for leather chappals will be good enough for this one too. If the use is less, one can even expect to wear it for a couple of years.

Though Multicare makes such chappals for all sizes, Child and Gents models have very low demand. At present, womenfolk constitute the lions-share of the clientele. Joseph puts the share of ladies chappals out of the total demand at 70 per cent.

Custom - made

Interestingly, all these chappals are custom-made. Before pasting the cut-out areca leaf sheath, explains Joseph, we should know which strap has to be fixed to this. In other words, gumming the areca leaf top to the rubber sole and fixing the strap has to be done in one stretch. Because of this technical bottle neck, the company cant keep chappals ready.

This chappal, according to Joseph, has given very positive results for those suffering from cracking of back foot and corn problem. People who spend long hours under air-conditioned atmosphere have to take extra care about their nose-tip and feet. Areca leaf sheath chappal, he claims, gives the required warmth to the feet in such a situation.

![]() Beautiful strap pattern liked by upper-class customers. Pic: Shree Padre.

Beautiful strap pattern liked by upper-class customers. Pic: Shree Padre.

Another area where this footwear has found acceptance is in Ayurveda Vaidyasalas of Kerala. In the treatment room called valachchil, the floor is always smeared with oil. As such, it remains slippery posing threat to the inmates. Chappals made from PVA and PVC is very dangerous in such conditions as it will slip.

Strap constitutes the costliest part of these chappals. Broader the strap, chappal turns costlier. Multicare gets these straps pleated by women belonging to Kudumbashree unit.

An experienced lady can make 50 sets of straps a day. As this process is completely manual, it is one more bottleneck in the production line. According to Joseph, the straps incur sixty percent costs of the chappal sets.

![]() For the men. Pic: Shree Padre.

For the men. Pic: Shree Padre.

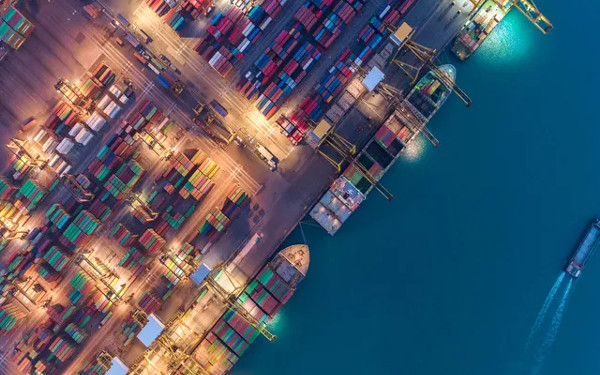

These are mainly meant for the richer class. Though it has good encouraging response overseas, cheaper synthetic products from China, says Joseph, are offering tough competition. Since the market is not on big scale, employing the women round the year to make straps is difficult. We are banking only on mouth to mouth publicity. The market is picking up in a very slow pace. As such, this venture, as it stands isnt remunerative, complains Joseph.

There is another marketing disadvantage. Such footwear is only sold through handicrafts emporias and not by mainstream shoe shops. But since chappals are not the only products of Multicare, the firm is pushing on despite challenges. R&D activities are continuing hoping that the market will take an upward turn in future.